docoyo in manufacturing

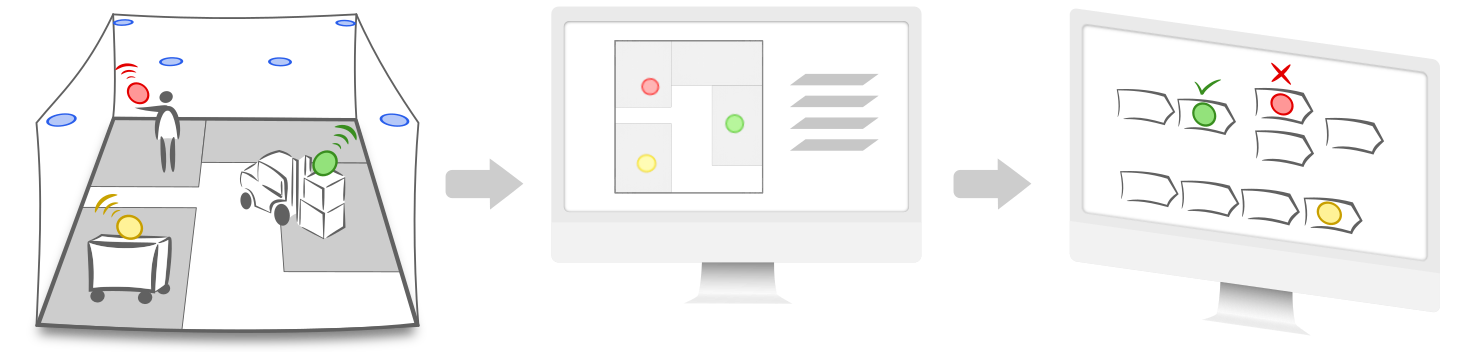

How it works

We attach beacons, UWB tags, RFID tags, and barcodes to objects. Additionally, receivers are installed in the building. The generated location and process information are sent to docoyo.Trackable and processed from there. Via your computer or mobile device such as smartphones or tablets, you can easily access your data.

Monitor order status

Get an overview of the current status of your orders in real time. Which orders are currently processed? In which position are they, and when will they be completed?

This information is not only valuable for production planning and process optimization but also help reliably answer customer requests concerning their orders.

Allow traceability of products

docoyo.Trackable displays for all orders the processing steps and movement histories. Thus, it is possible to completely trace orders at any time so that you are well-prepared for audits, documentation required, analysis of quality issues, reclamations and customer requests.

Support daily detailed planning

See at a glance which articles are in processing or in stock and which semi-finished articles are spread over the production. Thus prevent overproduction or overstock and decrease capital lockup. docoyo.Trackable also makes it possible to discover bottlenecks in the production process and to react accordingly.

Use the alerting feature to meet target amounts in zones and wait times.

Finding tools

Heavy tools, tools for special purposes or cost-intensive tools are usually only available in a limited amount but are needed in different locations. Reduce search times for tools and save valuable work time.

Analyze productivity

docoyo.Trackable delivers important key performance indicators for monitoring and controlling processes. Determine productive versus non-productive versus put-through times, match actual with target amounts and compare different shifts/days/months.

Recognize waste

Kinds of waste are manifold and reach from produced waste to unnecessary distances covered. docoyo.Trackable provides transparency on the basis for reducing waste. See reasons for waste summed up in your statistics. Generate movement profiles such as assessments of movement paths in the form of spaghetti diagrams or concerning localization and duration in the form of heat maps.

Perpetual or physical inventory

Perpetual inventory: Keep track of your articles and easily draw complete lists of your inventory anytime, including current location and last point in time recorded, without the need for manual scans.

Physical inventory: Track the inventory progress via your live dashboard. Compare actual to target inventory and monitor deviations such as equipment not found or found but not expected.

Features von docoyo.Trackable

- Live Tracking & History

- Monitoring & Alerting

- Order and Process Tracking

- Automated Inventory

- Reports & Statistics

- etc.