Realtime Tracking

- in manufacturing

- in logistics

Technologies

Turn location data into business success

What is location data?

docoyo.Trackable turns location data into process information.

Our software automatically makes processes in industrial manufacturing transparent – even without scanning or manual input. Vendor-independent and quick to implement.

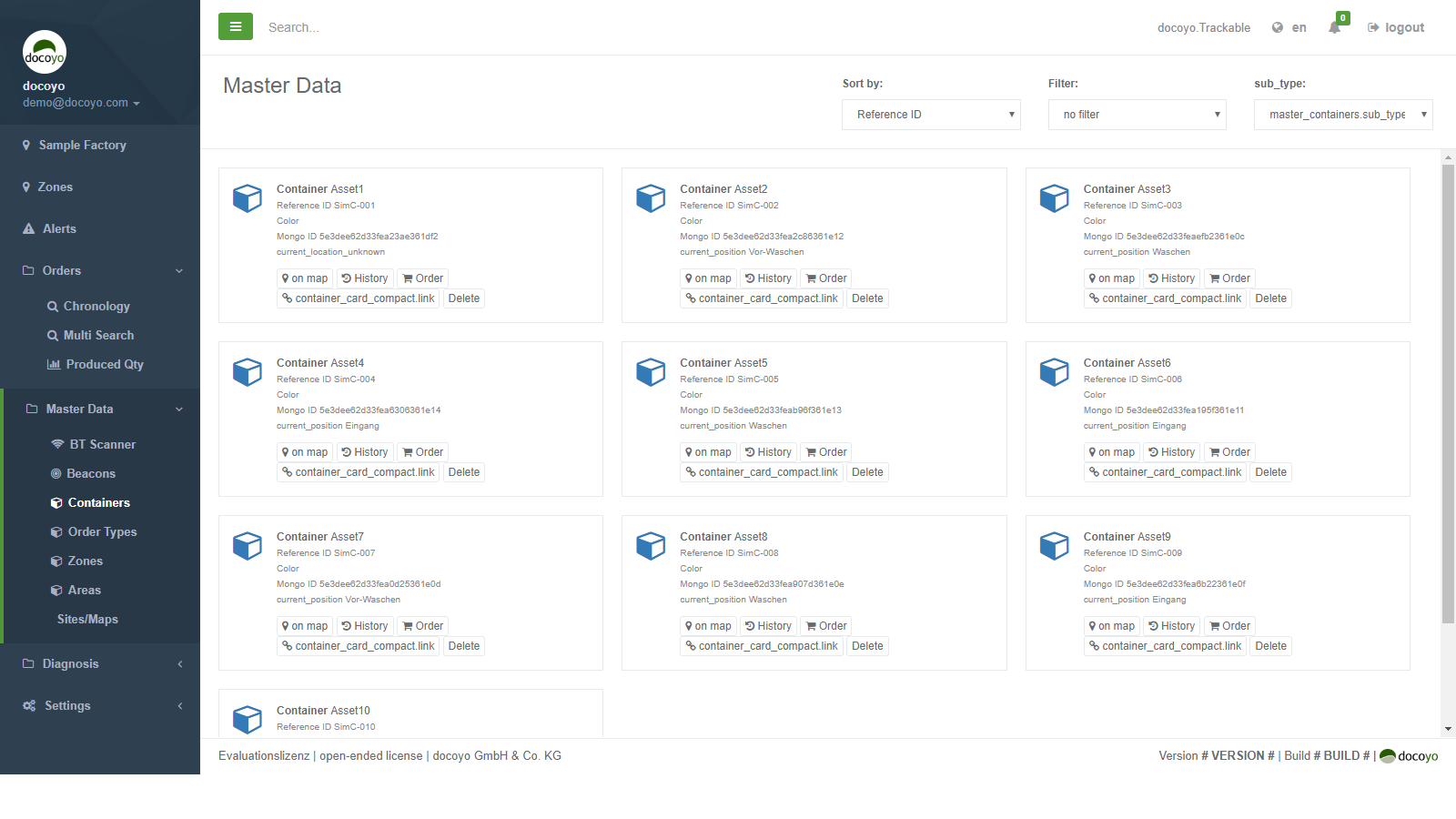

Features

Functions that make work easier

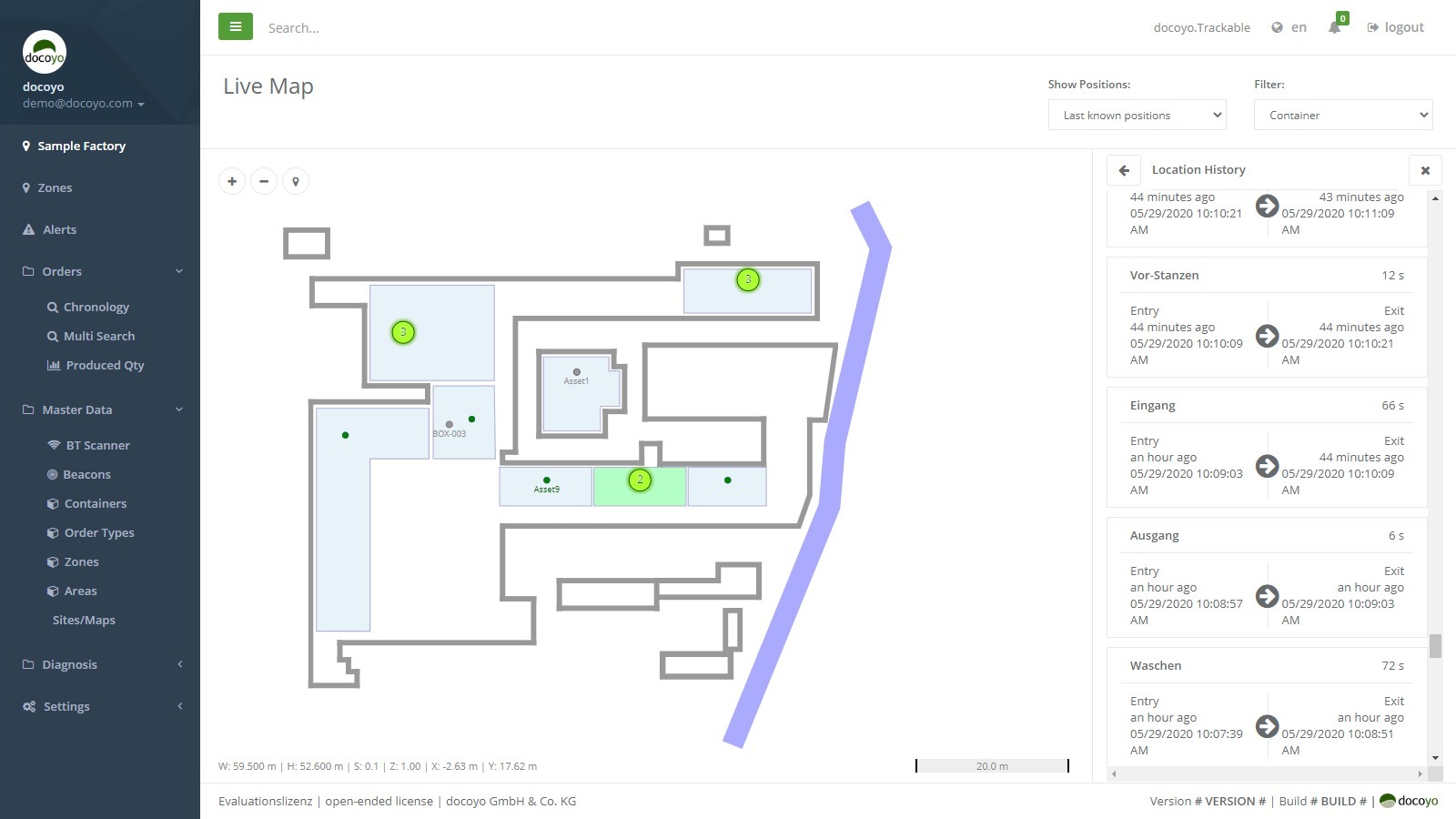

Search & Find

Locate workpieces, load carriers, or tools in real time on a facility map—no more time wasted searching.

Track & Trace

Automatically capture the progress of your manufacturing and logistics processes. Always stay ready to provide answers to customers and management.

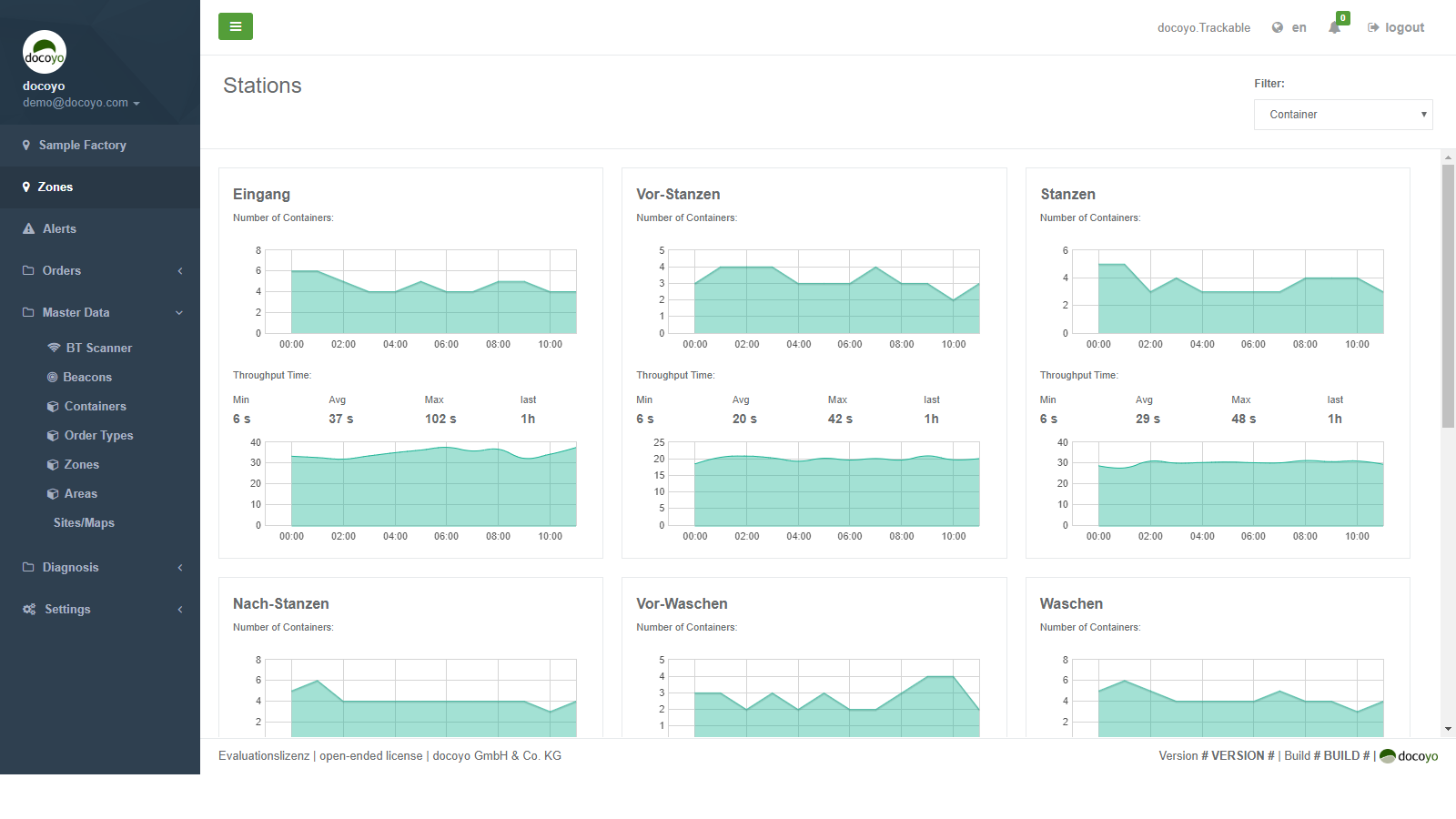

Dashboards

Use custom dashboards and statistics to make faster, more reliable decisions.

Complete history

Trace material and object movements seamlessly—ideal for audits and quality requirements.

Monitoring

Receive automatic notifications when processes deviate from the norm or when a workpiece is ready for the next step—via email, Teams, SMS, or REST API.

Connectivity

Benefit from a comprehensive toolkit that allows our software to be easily adapted to your processes and integrated with your existing systems.

Features

How it works

1.

The tracking technology is installed in your buildings or production halls. We advise you on selecting the right technology.

2.

Tags are linked to the order, workpiece, load carrier, or similar object via a scan.

3.

Our system automatically tracks the object from that point on. You can work with it directly in the software.

4.

At the end of the process, the tag is detached—via scan or automatically—and reused for the next cycle.

All standard. Yet tailored to your needs.

With docoyo.Trackable, most functions typically required for tracking are already included as standard—ready to use and field-proven.

At the same time, we know that every company is different. That’s why we provide flexible tools and interfaces to implement individual requirements quickly and cost-efficiently.

You benefit from the reliability of proven standard software—without giving up solutions tailored to your business.

Fits every industry

Automotive suppliers

Ensure quality and compliance. Track components seamlessly and avoid delays.

Laboratories

Create precise documentation through automatic tracking of samples and materials, including sensor data capture.

Mechanical engineering

Reduce search times. Speed up handovers between process steps and minimize idle times.

docoyo.Trackable is suitable for many industries. Wherever workpieces, materials, or goods are moved along your processes, automatic tracking and process monitoring provide many advantages.

Electronics manufacturing

Optimize machine utilization in real time based on automatically captured workload at different stations.

Wood processing

Reduce search times across widely distributed intermediate storage areas. Automate your workflow.

More than software – your solution directly from the manufacturer

With standard software, companies are often left alone when it comes to customization. External consultants are frequently required for integrations and adaptations.

With docoyo, it’s different.

You get a complete solution from a single source. We support you personally from the first conversation to successful deployment.

That means a solution perfectly tailored to your company—directly from the development team that knows every line of the product.

Frequently asked questions

Still have questions?

See the software in action.

Let’s talk—free of charge and without obligation. We take time for your individual situation and provide personal advice.

No sales fluff. Promise.